Repair is the Real E-waste Solution: International E-waste Day Podcast

When most people think of e-waste, they picture piles of old laptops or discarded phones. But as Ben explains in the latest Repair Don’t Waste podcast for International E-Waste Day, the reality is very different for industry. “Behind every factory line, transport network, and energy project there are countless circuit boards quietly controlling the operation,” he says. “When they fail, companies are left with a choice: repair or replace — often choosing the latter out of convenience.”

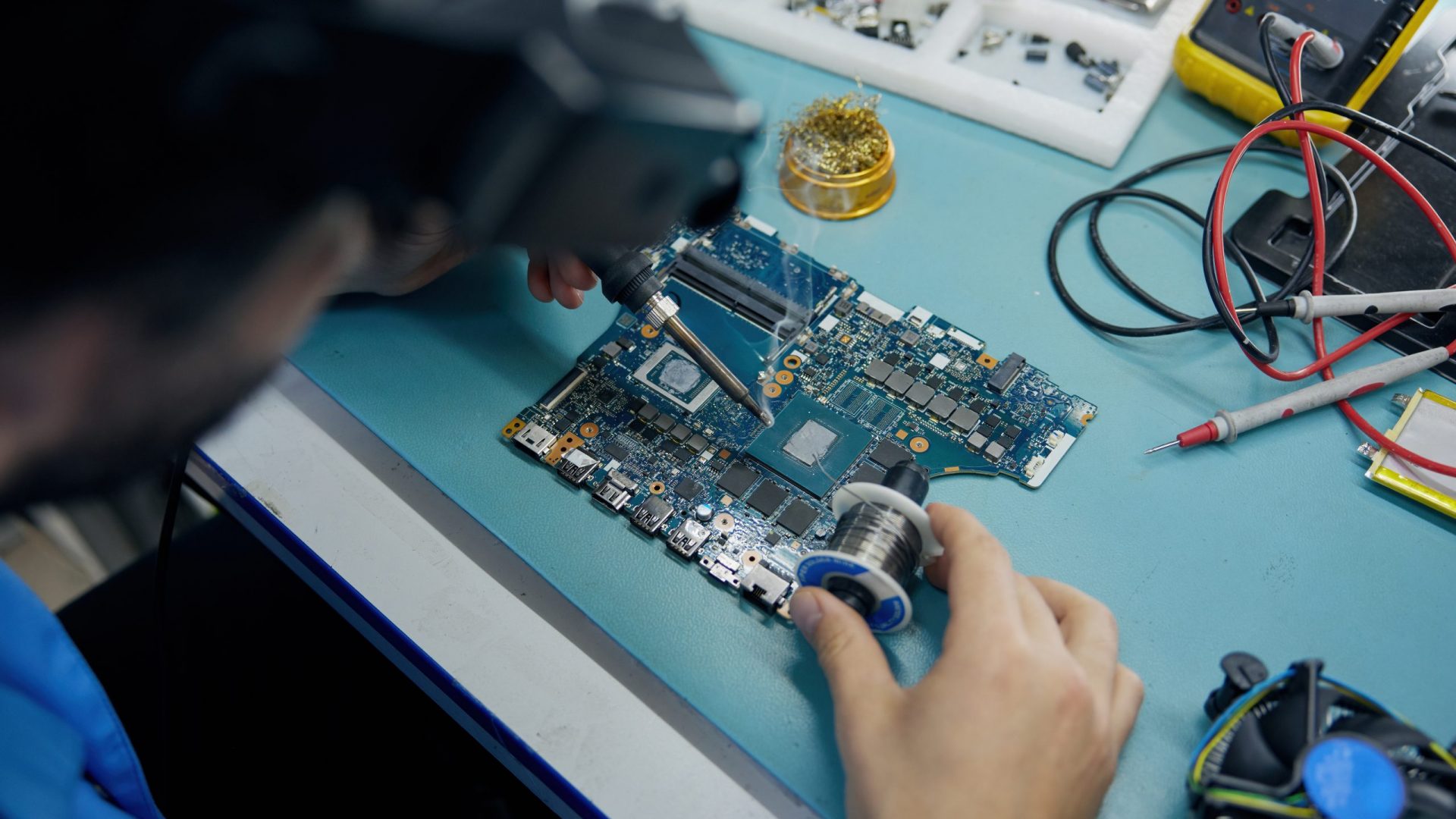

Those small boards, often hidden inside machines and control systems, might seem insignificant, but they’re the brains behind entire major operations. A single fault can bring down entire production lines, stop wind turbines, or freeze transport networks. Yet, as Willian Santos from ABI Electronics points out, they’re frequently overlooked. “The majority of people responsible for asset management policies don’t really understand how these systems work,” he says. “They come to us and ask where our electronics are used because obviously, they aren’t known. They are classified as minor components… We’ve had people from big organisations in the renewable energy sector say they don’t even have access to the data, they don’t know how much they’re spending on electronics repair or replacement.”

That lack of awareness leads to waste and unnecessary spending on new parts. Each wind turbine, Willian explains, uses between twenty and thirty circuit boards, each costing thousands of euros. Across more than 56,000 turbines worldwide, that adds up to billions invested in electronics, most of which could last far longer if properly maintained. “You can’t really call yourself a green energy company if you are producing e-waste,” he says. “If your maintenance strategy is based on replacing like for like every time a capacitor fails, you’re adding to the fastest-growing waste stream in the world.”

Repairing instead of replacing is not only better for the environment, but also business. “If you don’t manage these challenges properly, it’s your company’s profitability that will be affected,” Willian warns. A repaired circuit board can save about 90 percent of the cost and produce 85 percent fewer emissions than buying a new one. It also reduces exposure to supply chain delays, tariffs, and cyber risks. “If you are delegating your maintenance strategy to the supply chain, and if you let the supply chain regulate the pricing, you’re never going to be in control.”

One example shows how powerful that shift can be. In Brazil, a technician working for GE grew tired of watching valuable boards being thrown away. He started repairing them on his own time using traditional tools, saving his company so much money that management took notice. “In four years, this operation saved GE over $20 million,” says Willian. “They managed to repair very quickly, even during the pandemic when some spare parts were on long lead times. What started as one person’s frustration turned into a worldwide repair programme.”

Both Ben and Willian agree that this change has to start at the design stage. “Systems need to be designed for repair, for circularity, for sustainability,” Willian says. “We need to move away from bespoke designs that make maintenance difficult and replace them with modular designs and standard connectors. Operators should have access to at least the bill of materials and schematics, so they know which components are on their boards.” ABI Electronics follows this philosophy themselves, helping customers repair locally by sharing parts lists, schematics, and guidance instead of locking them into expensive service agreements. “If we can do it,” he says, “the rest of the equipment manufacturing industry can do it as well.”

Obsolescence is another growing threat that drives unnecessary waste. “When I started my career 25 years ago, something obsolete was a piece of equipment made 40 years prior,” Willian recalls. “Nowadays, we’ve seen complete wind farms, solar plants, and rail systems launching with many of their vital systems already obsolete.” Through his involvement with the International Institute of Obsolescence Management, he’s been promoting a proactive approach, embedding obsolescence management into product design and maintenance planning from the very beginning, rather than treating it as an afterthought.

Repairing electronics, he insists, isn’t just about fixing parts, it’s about resilience. It gives companies more control, reduces dependency, and strengthens both profitability and sustainability. “We don’t repair PCBs,” he explains of ABI’s role. “We supply the equipment and help you overcome these challenges within your organisation in a more sustainable manner.”

As Ben concludes in the episode, the message for International E-Waste Day couldn’t be clearer; industrial e-waste is not inevitable. “Every board that’s repaired instead of replaced saves resources, cuts emissions, and keeps industries moving in a smarter, more sustainable direction,” he says. “Repairing doesn’t just reduce waste but redefines what responsible industry looks like.”

The Repair Don’t Waste podcast continues to highlight these stories from across the world of manufacturing, renewables, and engineering, where repair is not only possible, but essential. The latest episode featuring Willian Santos from ABI Electronics is available now on Spotify and YouTube.