Readiness Through Repair: How the US Military is Strengthening Capabilities with Right to Repair

In the high-stakes world of defence, mission readiness is everything. A single malfunction can ground fleets, stall strategies and cost millions. But what if the key to stronger equipment resilience isn’t in buying new, but in developing strategies to repair what we already have? That’s the powerful mindset shift now underway in the United States military. In April 2024, the Secretary of the Army announced plans to embed Right-to-Repair (R2R) provisions into all new and existing Army contracts. This marks a pivotal moment that recognises when the ability to repair is limited by manufacturer restrictions, readiness, efficiency, and safety are compromised.

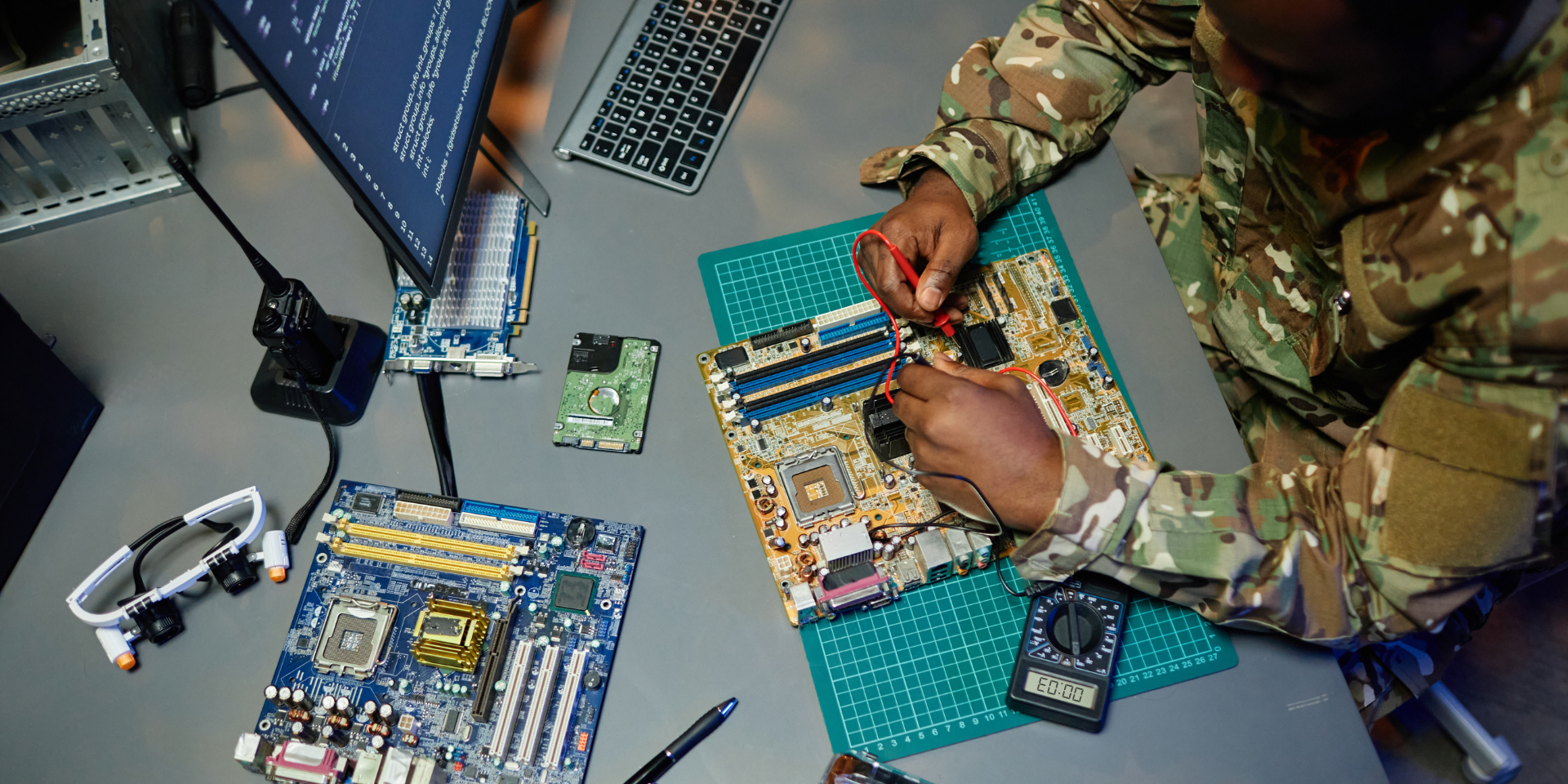

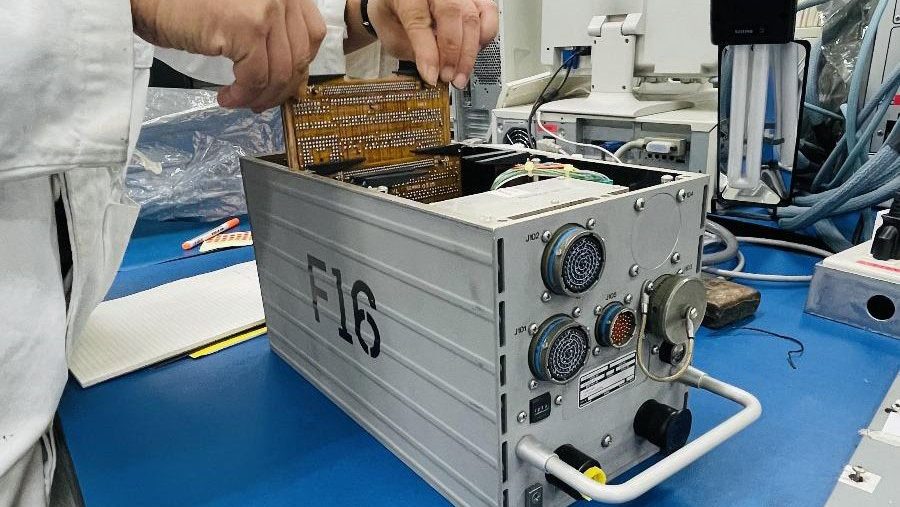

For decades, military technicians have faced frustrating challenges. Despite their training, they are often prevented from fixing their own equipment, manufacturers have locked repair behind proprietary tools, withheld software access, and demanded that only brand-authorised technicians perform maintenance. This model, long accepted in consumer electronics, has infiltrated mission-critical defence systems and the consequences are severe. In one case, a CT scanner at a field hospital sat idle because the military couldn’t obtain a microcontroller replacement from the manufacturer. The official solution? Buy a new device. In another, a RQ-11 Raven drone that crash-landed was sent back to the manufacturer for repairs at a staggering cost of $26,000, even though soldiers in the field were capable of performing the fix. Multiply that inefficiency across the thousands of systems used daily, and you have readiness issues costing taxpayers billions. According to the U.S. Government Accountability Office, operating and support costs can account for up to 70% of a system’s total lifecycle expense. When equipment can’t be repaired promptly or affordably, those costs escalate exponentially.

The new Right-to-Repair initiative is designed to reverse that. By mandating access to technical data, diagnostic software, and spare parts, the Army aims to give its own personnel the power to maintain and restore equipment without unnecessary third-party dependence. This shift could save taxpayers tens of billions of dollars over time while improving mission responsiveness, and Americans overwhelmingly support it. In a national survey conducted by the US PIRG, 74% of voters said they back congressional action to guarantee the military’s right to repair its own hardware. The Army’s embrace of Right to Repair sends a powerful message, that repair isn’t a liability but the key to operational freedom. The ability to repair in the field reduces downtime, builds self-reliance, and strengthens the bond between operators and the tools they depend on. In military terms, repair translates directly to resilience.

Beyond defence, the lesson applies everywhere. When manufacturers, energy providers, and transport industries face similar restrictions, they experience the same inefficiencies the military is now working to overcome. The common truth is repair access leads to stronger performance, reduced waste, and smarter spending, and if the U.S. Army, one of the most complex and security-sensitive organisations in the world, can move toward open repair, then so can every other industry.

At Repair, Don’t Waste, we see this as proof that repair culture is applicable everywhere. Whether it’s a soldier fixing a drone, a technician restoring an industrial board, or a consumer repairing their smartphone, the principle is the same: when you empower people to repair, you save resources and extend the life of every asset, improving resilience and saving the environment.