Saving Millions, One Circuit Board at a Time: Repair Don’t Waste in the North American Car Brake Industry

Car brake manufacturing in North America is a significant industry, with a market size estimated to reach $10.2 billion by 2025. However, this sector, like many others, faces a growing challenge: the rising cost of automation equipment and spare parts.

A key culprit in this cost increase is the price of complex circuit boards, essential components for modern CNC machines. Replacing a single faulty circuit board can be incredibly expensive, leading to extended downtime and significant financial burdens.

This is where the Repair Don’t Waste movement comes in, offering a practical and sustainable alternative. Our story perfectly exemplifies its impact.

A Real-World Example: Saving Time and Money with Repair

Rassini, a prominent car brake manufacturer in Mexico and a proud member of the Repair Don’t Waste movement, faced a dilemma. One of their brand-new CNC machines went down straight after commissioning due to a faulty circuit board. Their usual supplier, a major Japanese brand represented by a Mexican distributor, informed them a replacement board would take at least a month to arrive.

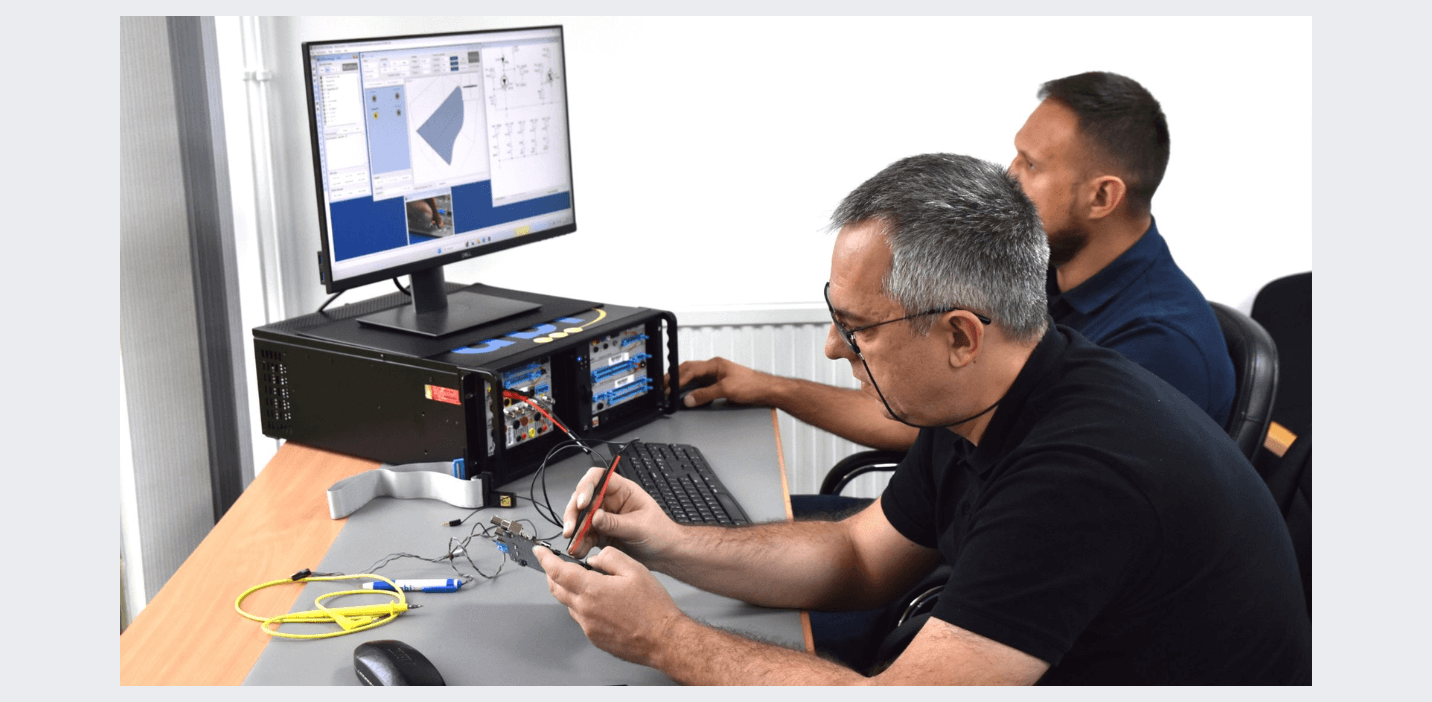

This delay would have caused costly production downtime. However, Rassini, armed with the Right To Repair principle and their secret weapon, a specialist circuit board diagnostic tool, were able to act swiftly.

After receiving the green light from the manufacturer’s representative, Rassini’s technicians diagnosed and repaired the faulty circuit board within two hours, getting their CNC machine back up and running. This swift repair not only saved Rassini a significant sum from a replacement but also, minimized production disruptions. The efficiency and effectiveness of the repair process left the Japanese distributor impressed.

Beyond Cost Savings: The Broader Impact of Repair

The Repair Don’t Waste movement’s benefits extend far beyond immediate cost savings. Here’s how:

- Millions Saved: By prioritising repairs over replacements for circuit boards and other electronic components, manufacturers worldwide can save millions of dollars collectively.

- New Jobs and Career Progression: The growing focus on repair creates opportunities for new jobs in electronics repair and maintenance, offering exciting career paths.

- Environmental Benefits: Repairing electronics significantly reduces e-waste, a major environmental concern. Less waste translates to a healthier planet for everyone.

Rassini’s story is just one example of how Repair Don’t Waste is revolutionising the car industry in North America and other parts of the world. By empowering companies to prioritize repairs, we’re not only saving them money but also creating a more sustainable future for the entire automotive sector.

Join the Movement:

Together, we can build a future where repair is the norm, not the exception. Explore the resources offered by Repair Don’t Waste and ABI to learn how your company can benefit from this transformative approach. Since launch in 2015, over 150 global organisations joined Repair Don’t Waste saving an estimated US$50 Million a year and truckloads of equipment from early disposal. Click here to send us your enquiry!