CHIPS Act: start repairing circuit boards now or be left behind!

Signed into law in August 2022, the U.S. Government’s CHIPS Act has been dubbed the most disruptive change to affect the electronics industry in a generation with serious consequences for its supply chain expected to last well over a decade. In a desperate attempt to recoup semiconductor manufacturing capacity in the US – which dropped from 40% of global supply in the 1990’s, to just 12% today – the administration has pledged $52.7 billion in federal subsidies, much of which will go towards the creation of semiconductors fabrication plants. The European Union has also passed a similar act as part of the “Chips for Europe” investment plan which is planned to span to 2030 and gain over 20% of the global market share in the semiconductor industry by then. Britain has also followed in their footsteps, guaranteeing £1 billion in funding over the next 20 years for strengthening the UK’s prowess in the sector. Repair, Don’t Waste ask: what are companies going to do whilst these projects are in their infancy for the next 10-15 years, whilst chips are highly scarce, and whilst net-zero pressures are continually mounting? We believe that repairing and maintaining existing electronic circuit boards, a.k.a PCBs, offers the perfect solution to this myriad of concerns.

Microchips are the gold of the modern age. Every single piece of complex technology – from military, aerospace, communication, automotive, manufacturing and AI – have microchips driving and controlling them. Without chips, the modern world that we know and the future that we aspire to would not exist. So, it is no wonder that after years of offloading semiconductor manufacturing to East Asia, the U.S and Europe are investing so much in reshoring this vital industry.

As shown in the COVID-19 pandemic, chip shortages and supply chain issues can bring manufacturing to a grinding halt. The shortages are only just recovering nearly 3 years after the pandemic started, which has had a profound effect on industry and productivity. Additionally, the pandemic brought an increased consumer demand for electronic products, from appliances to computers to cars. Add this to increased electrification globally – the starkest example being the boom in EV transportation – and you can easily see why assured supply of microchips is so critical.

Yet for the time being, electronic chips are often hard to procure, are being supplied from far afield and many are being made obsolete by their manufacturers with little to no warning. What is a booming business to do in lieu of European and American chip supply chains? For many, they already have the chips they need – in faulty PCBs.

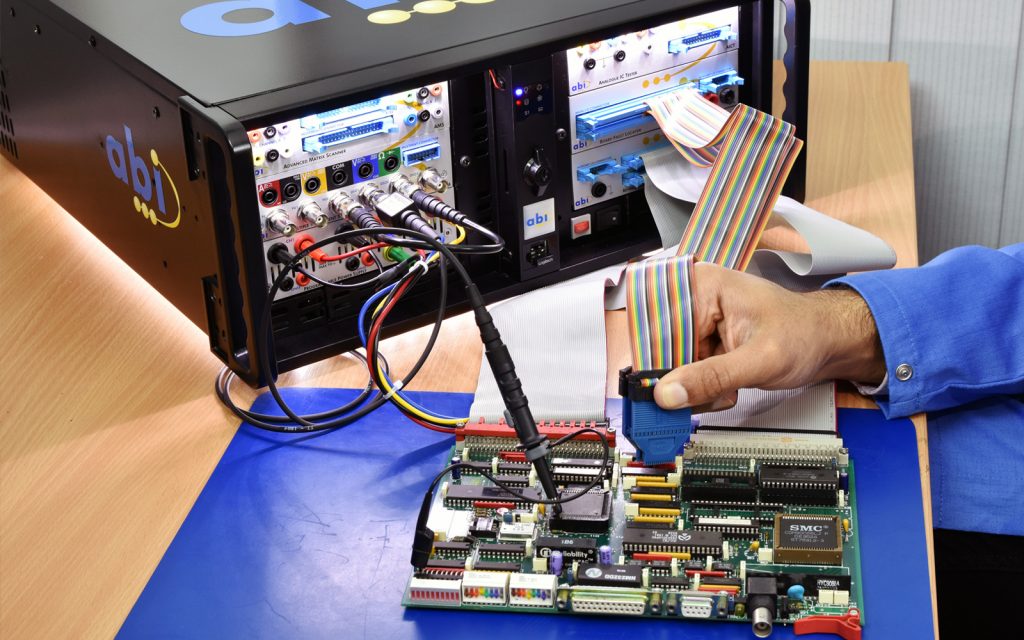

By repairing a circuit board from a critical system, multiple chips can be saved from becoming E-waste and the system can be reinstated. By troubleshooting a PCB with specialist diagnostic equipment, it is often found that a component worth just a few dollars or less is the faulty culprit and can easily be replaced using industry repair standards. This saves time from procurement and production processes, alongside obvious financial and environmental savings. The Repair, Don’t Waste mindset can ensure that crucial systems are supported and maintained to the highest standard for years to come.

A further concern we have for these new investments in the semiconductor industry is the shocking lack of hands-on education in electronic engineering courses and the lack of interest or knowledge in electronic repair. Electronic engineering degrees in the UK are more concerned with design than the physical work needed to repair those designs when the hardware degrades. With such adventurous plans for semiconductor fabrication plants, we believe that Western governments must invest in the practical education of engineering students, otherwise, who will manage these microchip powerhouses? Semiconductor design and manufacturing are far from unskilled work. Repair, Don’t Waste believes that focusing on rehauling electronics education is crucial to re-enter the global semiconductor industry as a serious player.

We are totally failing #electronics engineering students in this country. Actually, most countries are. The industry cries "Right To Repair!" while universities and colleges work to eliminate the practical teaching of electronics. #ukmfg #STEMeducation #circulareconomy pic.twitter.com/1ikLggM6bc

— Repair, Don't Waste! (@RepairDontWaste) May 16, 2023

A repair-first strategy can help businesses support and manage their critical systems whilst American and European microchip supply chains take form, and well beyond that. Building and strengthening an industry from the ground up will take years, potentially decades, by which point the world will be ploughing headfirst into net-zero and sustainability initiatives. Repair, Don’t Waste enables companies freedom from the unpredictability of chip sourcing, alongside contributing to ESG targets and reducing their E-waste footprint.