In-house repair helps wind turbine giant save tons of money and the environment

Many of the world’s energy giants, even those in the renewable sector, are stuck in the unending cycle of make-break-replace on an enormous scale. Every piece of electronic equipment that goes into generating the power that our modern world needs have the potential to fail, which can be catastrophic for output levels. However, if an electronic board fails, many suppliers simply buy and install a replacement as soon as is possible to restore production, without even considering the monetary and resource losses that are created in this ‘simple’ act.

GE Renewable Energy are different. Over the past 4 years, GE have saved 20 million dollars by consigning the act of throwing away a faulty PCB to the past. Their strategy now? Repair, Don’t Waste.

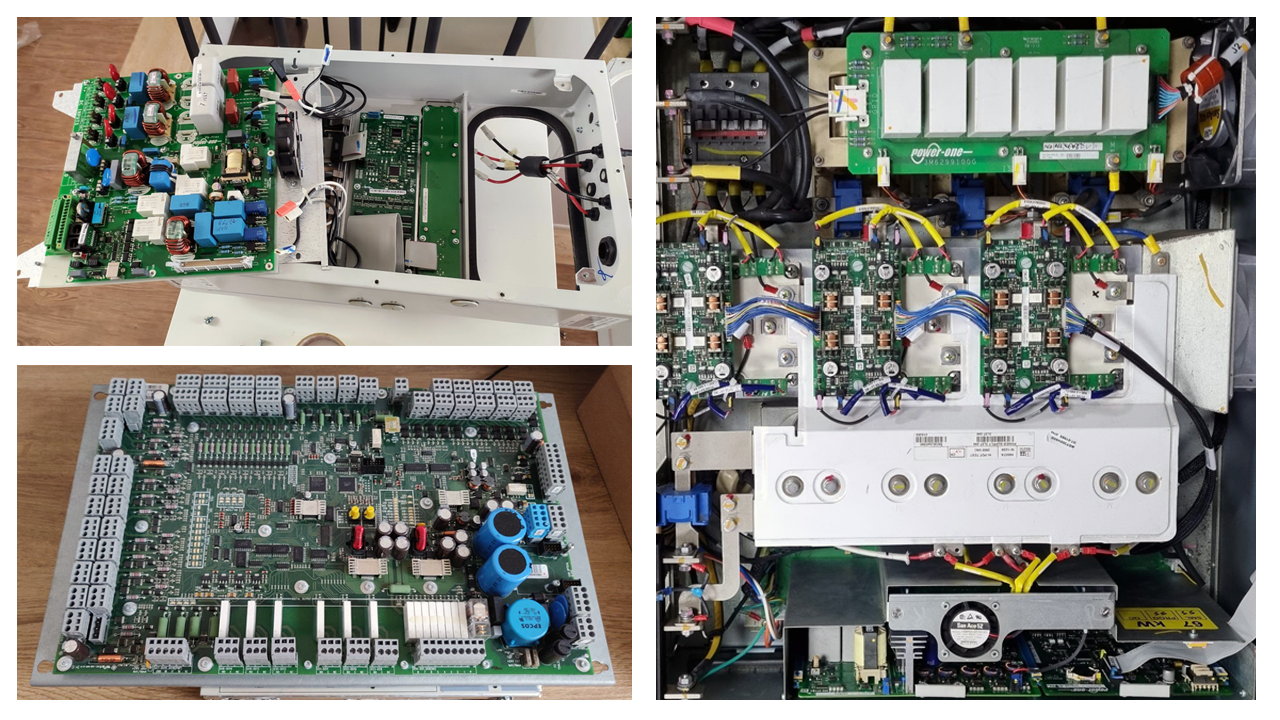

A trailblazer of innovation, their successful investment in in-house repair facilities to troubleshoot and repair faulty boards has spread to 8 global locations with even further expansion planned as the race to zero continues. In 2018, GE had never even considered that repair and maintenance would be their biggest ally in keeping their highly complex electronic wind turbine systems running. But even the biggest energy providers are not immune to the callous nature of OEM ‘support’.

Before GE invested in test and measurement equipment for board repair from ABI Electronics at a North American site, they experienced a damaging standstill due to lack of spare boards and were quoted a 9-month lead time by their OEM, thanks to a melting pot of component shortages and lead-time delays. With this situation occurring, a batch of broken and obsolete boards were sent to another GE site with an in-house repair lab – all the faulty boards were diagnosed and repaired within a week.

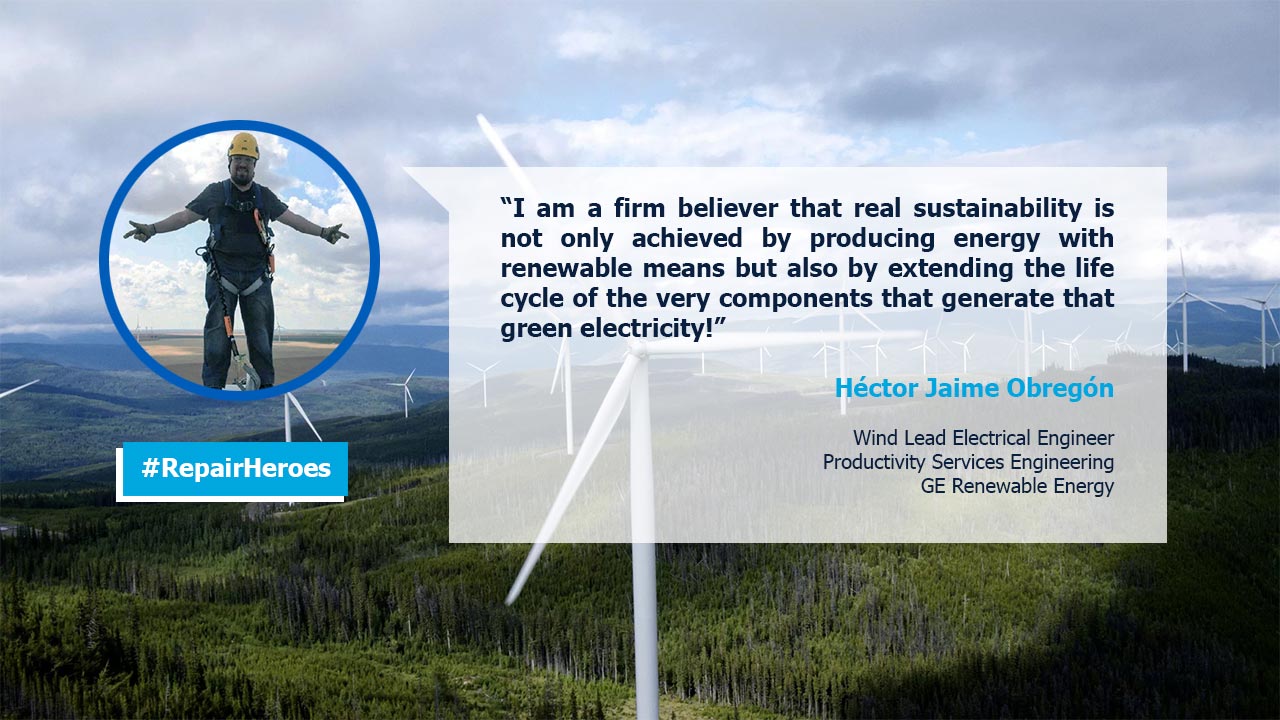

GE locations around the world embrace the Repair, Don’t Waste movement for a multitude of reasons. In addition to saving money and time, repairing rather than replacing electronics helps companies who are focused on net-zero emissions and sustainability to contribute to carbon reduction targets by significantly reducing E-waste, which is expected to grow considerably with increasing digitalisation.

We are delighted that GE have invested so much into the Repair, Don’t Waste movement and are seeing the amazing results that repair and maintenance can have in even the most specialist applications. We look forward to hearing about their continued successes as #RepairHeroes, and we encourage other organisations – regardless of size – to follow their remarkable example.

Get in touch to learn more about the technology, training, and certification available to implement an effective in-house repair facility in your business! Email info@repairdontwaste.com and a member of our team will get back to you.