Automaker acts to eliminate E-waste through in-house repair and maintenance

Sustainability in the automotive industry is for many a strategy that will spearhead a new, circular future. And in many ways, the production of electric vehicles en-masse is one of the first tangible changes we are seeing happen worldwide in response to climate pressures. However, the manufacturing processes to create these carbon-neutral cars are strikingly similar to traditional methods, which create an astonishing amount of waste.

Over the past 5 years, auto manufacturers have begun to mitigate the amount of waste going to landfill by recycling and incinerating up to 87% of the waste produced in their plants. With around 48kg of total waste generated per vehicle produced, and with production of EVs expected to boom in line with increased demand, even 10% of this waste going to landfill is far too high. Recycling raw materials for reuse is an effective way of reducing waste, but what happens to products such as electronic circuit boards, consisting of dozens of components and different metals, that cannot be recycled so simply?

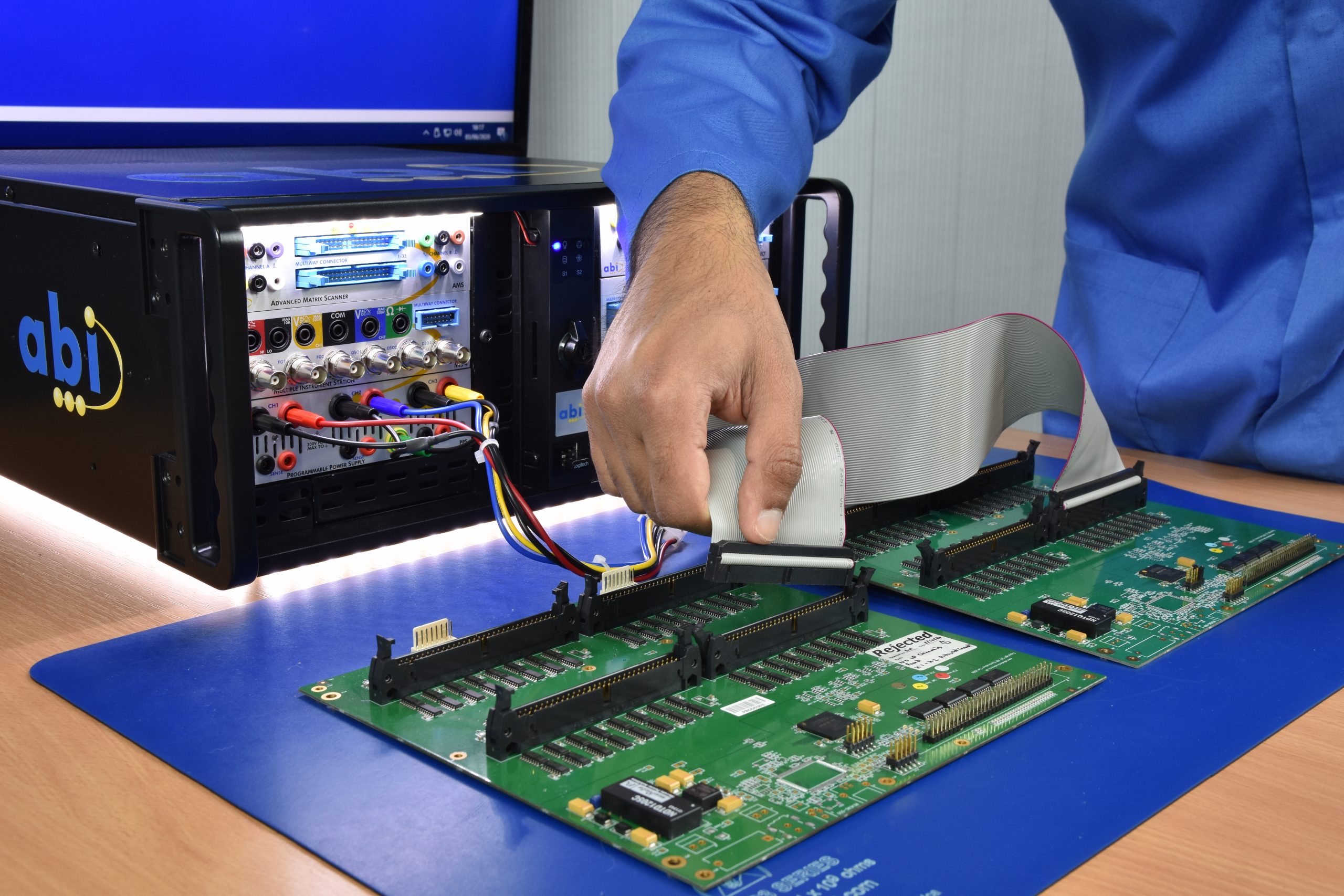

PCBs are commonplace in all factories around the world – they are the brains behind CNC machines, conveyor belts, robotic arms – and modern-day production would be near impossible without them. A single manufacturing site might require for instance, several thousand servo controller circuit boards to operate the assembly line robots. When these PCBs fail due to degradation or faulty design, manufacturers are often found in the difficult situation of sourcing a replacement board at great cost – both monetarily and environmentally – whilst halting production lines and causing further expense. One of the world’s largest automakers is pioneering an alternative to replacing circuit boards, by repairing them on-site in a matter of hours.

Stellantis, best known as the manufacturer of brands such as Citroen, Fiat and Jeep and is swiftly embracing the EV revolution. Stellantis are no stranger to establishing repair as a common practice, having operated a “Repair & Return” service since 2011 for complex electronic products in their cars. Now, they are taking the leap to extend the benefits of repair to their industrial-scale production machines with an initial investment in in-house specialist test and measurement equipment at their Brazilian plant.

By choosing to repair rather than replace circuit boards from highly advanced machinery, Stellantis is securing a multitude of benefits for their production process and beyond. Repair, Don’t Waste members around the world have seen significant decreases in production downtime, previously dismissed machines brought back to life, and total investment cost recovered in just 3 months of operation. Alongside this, Stellantis are ensuring their future stability in a world of hasty obsolescence and complete lack of OEM support. With so much focus on reaching ESG and sustainability goals in an increasingly diminishing time frame, their investment in specialist test and measurement equipment and training gives Stellantis the upper hand in meeting sustainability targets and reducing their contribution to global E-waste.

As the demand for carbon-neutral vehicles increases, so must our analysis of their manufacturing – can a car really be truly sustainable, when produced via unsustainable practises? Repair, Don’t Waste help companies around the world to build a ESG toolkit – to reduce E-waste, fight programmed obsolescence, and meet sustainability targets to benefit everyone involved. Circular practises in the automotive industry need to start at a manufacturing level in order to create vehicles that are truly devoid of waste. We are incredibly excited to welcome Stellantis’ flagship site to the Repair, Don’t Waste movement, and we hope they may be the catalyst for an automotive revolution.